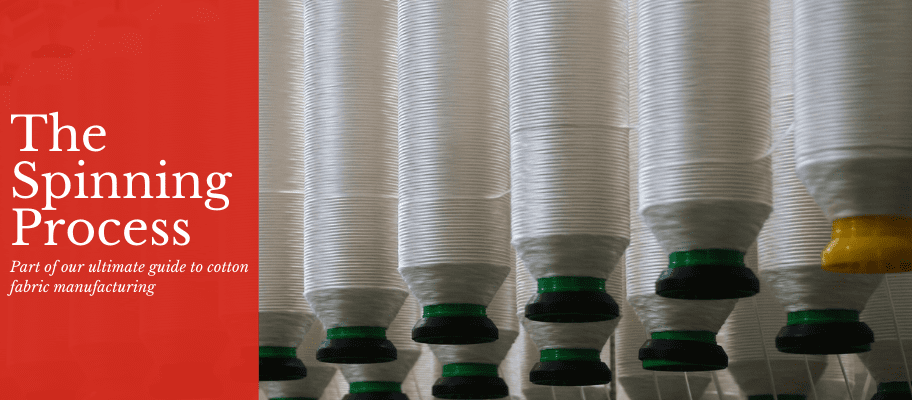

The spinning devices take fibers from the sliver and rotate it up to 2,500 revolutions in a second twist that makes fibers into a yarn for weaving or knitting into fabrics. looms work at great speeds, interlacing the length-wise yarns (warp) and the crosswise yarns (filling).

What was the purpose of spinning cotton?

The spinning of cotton yarn is the initial stage of textile product processing. The process of producing yarns from the extracted fibres is called spinning. In this process: The strands of cotton fibres are twisted together to form yarn.

What is the purpose of spinning yarn?

spinning, in textiles, process of drawing out fibres from a mass and twisting them together to form a continuous thread or yarn.

What does spinning mean cotton?

Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin.

What was the purpose of spinning cotton?

The spinning of cotton yarn is the initial stage of textile product processing. The process of producing yarns from the extracted fibres is called spinning. In this process: The strands of cotton fibres are twisted together to form yarn.

Why is it necessary to spin fibres before weaving?

Answer: It is necessary to spin the fibre because when fibers are spun, they form a coherent whole. It keeps them together.

Why is cotton fibre spun into yarn?

Cotton in its raw state is not naturally strong. To make it into a strong yarn, it needs to be twisted or spun.

What is spinning method?

Which instrument is used for spinning cotton?

A spindle is a straight spike usually made from wood used for spinning, twisting fibers such as wool, flax, hemp, cotton into yarn.

Why is it called spinning?

‘Spinning’ has evolved as a generic term that consumers use to describe indoor cycling. But that is not what it is. The term is actually a trademarked term owned by a California company known as Mad Dogg Athletics. They trademarked the term more than 25 years ago for a wide range of products related to cycling.

Who invented cotton spinning?

Finally, in 1767, a breakthrough came when a Lancashire entrepreneur, Richard Arkwright (1732–92), devised a simple but remarkable spinning machine. Replacing the work of human hands, the water frame made it possible to spin cotton yarn more quickly and in greater quantities than ever before.

How do you spin cotton?

Overlap two to three inches of the lead yarn onto the cotton fibers. Twirl the spindle until the twist travels up the lead yarn and into the fibers. Pull gently on the fibers by pulling your fiber source hand back away from the spindle about three to four inches, and pinching the spindle shaft with the other.

What was the role of cotton spinning and weaving in Industrial Revolution?

The shortage of yarn to feed the faster looms sparked the development of more productive spinning techniques, triggering the start of the Industrial Revolution. In the early 1760s, James Hargreaves invented the spinning jenny and by the late 1760s Richard Arkwright had developed the water frame.

When was the cotton spinning machine invented?

Finally, in 1767, a breakthrough came when a Lancashire entrepreneur, Richard Arkwright (1732–92), devised a simple but remarkable spinning machine. Replacing the work of human hands, the water frame made it possible to spin cotton yarn more quickly and in greater quantities than ever before.

What was the spinning jenny used for in the Industrial Revolution?

James Hargreaves’ ‘Spinning Jenny’, the patent for which is shown here, would revolutionise the process of cotton spinning. The machine used eight spindles onto which the thread was spun, so by turning a single wheel, the operator could now spin eight threads at once.

How did the cotton mills revolutionize how Americans dress?

The mills completely changed how people dressed and the way they decorated their homes. By the 1830s, ordinary people could afford more clothing and poorer people began to copy the fashions of the well to do. Curtains and other decorative textiles appeared in houses.

What was the purpose of spinning cotton?

The spinning of cotton yarn is the initial stage of textile product processing. The process of producing yarns from the extracted fibres is called spinning. In this process: The strands of cotton fibres are twisted together to form yarn.

What is difference between spinning and weaving?

Weaving is the art of layering yarns or threads in a crosswise pattern to create continuous lengths of fabric, including patterned weaves and ribbons. Spinning is the process of making thread out of raw fibres. Weaving is the process of taking threads and making them into cloth.

What is spinning of fibers?

Fibre spinning is a process in which an extruded liquid polymer filament is continuously drawn and simultaneously solidified to form a continuous synthetic fibre. There are three fundamental processes for the manufacture of synthetic fibres: melt spinning, wet spinning, and dry spinning.

Is spinning is a process of making fibre?

Spinning is the process of making yarn from fibres. It is the process of drawing out and twisting fibres to join them firmly together in a continuous thread or yarn.

What is raw cotton called?

LINT: the raw fiber from the cotton plant which is pressed into. bales at the cotton gin.

What is spun cotton fabric?

A spun yarn is a twisted assembly of fibers formed into a linear strand. Since cotton (at a length of less than 2.0 inches) is a fiber less than 2.5 inches in length, cotton yarns are classified as short staple spun yarns. These yarns are characterized by their inherent hairiness and non-uniformity.