In 1794, U.S.-born inventor Eli WhitneyEli WhitneyEli Whitney Jr. (December 8, 1765 – January 8, 1825) was an American inventor, widely known for inventing the cotton gin, one of the key inventions of the Industrial Revolution that shaped the economy of the Antebellum South. New Haven, Connecticut, U.S.https://en.wikipedia.org › wiki › Eli_WhitneyEli Whitney – Wikipedia (1765-1825) patented the cotton gin, a machine that revolutionized the production of cotton by greatly speeding up the process of removing seeds from cotton fiber. By the mid-19th century, cotton had become America’s leading export.

What is spinning of cotton?

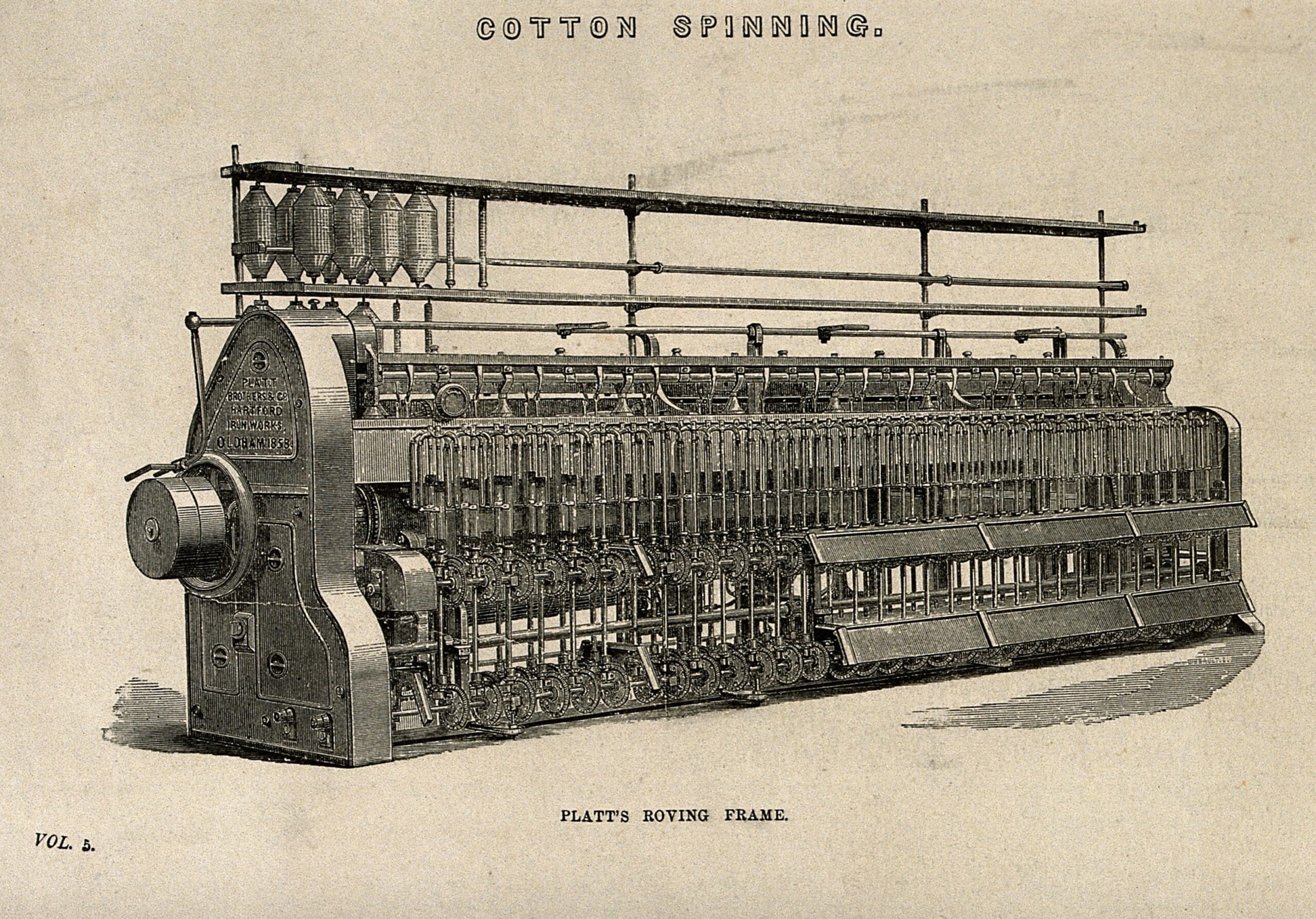

The process of producing yarns from the extracted fibres is called spinning. In this process: The strands of cotton fibres are twisted together to form yarn. The yarn is placed on the rings of the spinning frame and is allowed to pass through several sets of rollers, which are rotating at a successively higher speed.

What was a cotton Piecer?

Piecer – Worker in a cotton warehouse, who would lean over the spinning machines to repair broken threads (piecing them together). The work was normally done by children, since they had small fingers that could tie the broken threads together with ease.

Why is it called a cotton gin?

A modern mechanical cotton gin was created by American inventor Eli Whitney in 1793 and patented in 1794. Whitney’s gin used a combination of a wire screen and small wire hooks to pull the cotton through, while brushes continuously removed the loose cotton lint to prevent jams.

Why do we spin cotton?

The spinning devices take fibers from the sliver and rotate it up to 2,500 revolutions in a second twist that makes fibers into a yarn for weaving or knitting into fabrics. looms work at great speeds, interlacing the length-wise yarns (warp) and the crosswise yarns (filling).

Why is it called a cotton gin?

A modern mechanical cotton gin was created by American inventor Eli Whitney in 1793 and patented in 1794. Whitney’s gin used a combination of a wire screen and small wire hooks to pull the cotton through, while brushes continuously removed the loose cotton lint to prevent jams.

What is a spinner in a mill?

It looks big, but most industrial spinning machines were four times as long, with 72 or more bobbins per side – meaning that a single machine spun 144 or more individual threads at a time. The workers who ran the spinning machines were called spinners, and almost all of them were women.

What was a cotton Rover?

Cotton Rover: a textile industry worker, transferred cotton yarn onto bobbins.

What was a beamer at a cotton mill?

A beamer was an occupation in the cotton industry. The taper’s beam is a long cylinder with flanges where 400 plus ends (threads) are wound side-by-side. Creels of bobbins with the correct thread, mounted on a beaming frame wind their contents onto the beam. The machine is watched over by a “beamer”.

Does the cotton gin still exist today?

There are still cotton gins today that are currently used for separating and processing cotton. Cotton gins have changed over the many years since Eli Whitney first invented his. The cotton gins that are now used are much larger and more efficient although they still use the same ideas.

What is known as ginning?

Ginning is the process of removing the seeds and debris from cotton. The term comes from the cotton gin, invented by Eli Whitney in 1794. In modern ginning, the cotton is first dried to remove moisture, then cleaned to remove any burs, stems, leaves, or other foreign matter.

Which machine is used in spinning?

The spinning wheel was invented during the Middle Ages. A spinning machine is a piece of equipment which is used to spin fibers such as wool, flax, or cotton into thread, yarn, and related materials. Spinning machines come in a wide variety of shapes and sizes.

What did a cotton winder do?

Cotton Winder: worked in the textile industry, wound cotton thread. Cotton Yarn Gasser: de-fumigated raw cotton prior to use in the textile industry. Raw cotton from India was fumigated with methyl bromide to preserve it from pests.

Who invented the cotton mill?

Samuel Slater introduced the first water-powered cotton mill to the United States. This invention revolutionized the textile industry and was important for the Industrial Revolution. Born in Derbyshire, England, to a prosperous farmer, Slater apprenticed at a mill at age 14.

What is spinning process in textile?

spinning, in textiles, process of drawing out fibres from a mass and twisting them together to form a continuous thread or yarn.

What is spinning and its types?

1 Spinning Methods. Different spinning methods are available in making yarns, including ring-spun, rotor-spun, twistless, wrap-spun and core-spun yarns. Ring-spun yarns: This is the most widely used method of staple-fibre yarn production. The fibres are twisted around each other to give strength to the yarn.

What is spinning in manufacturing process?

Spinning is a process used to produce an axis-symmetric hollow shape by the application of lateral pressure from a forming tool, to a rapidly revolving circular blank of sheet material, causing it to assume the shape of a former that is rotating with it.

What is mechanical spinning?

The process of developing short fibres into long continuous yarns involves several steps and fibres assume forms of lap, sliver, roving and finally yarn. Lap formation through blending and opening. Lap to card sliver by carding process.

Why is it called a cotton gin?

A modern mechanical cotton gin was created by American inventor Eli Whitney in 1793 and patented in 1794. Whitney’s gin used a combination of a wire screen and small wire hooks to pull the cotton through, while brushes continuously removed the loose cotton lint to prevent jams.

What is a wool spinner called?

A great wheel (also called a wool wheel, high wheel or walking wheel) is advantageous when using the long-draw technique to spin wool or cotton because the high ratio between the large wheel and the whorl (sheave) enables the spinner to turn the bobbin faster, thus significantly speeding up production.

What are the types of spinning?

Different spinning methods are available in making yarns, including ring-spun, rotor-spun, twistless, wrap-spun and core-spun yarns. Ring-spun yarns: This is the most widely used method of staple-fibre yarn production. The fibres are twisted around each other to give strength to the yarn.

What were cotton mill workers called?

Boys were usually employed as doffers or sweepers, and men worked as weavers, loom fixers, carders, or supervisors. Mill workers usually worked six twelve-hour days each week.