Spinning is a process used to produce an axis-symmetric hollow shape by the application of lateral pressure from a forming tool, to a rapidly revolving circular blank of sheet material, causing it to assume the shape of a former that is rotating with it.

What is spinning in product design?

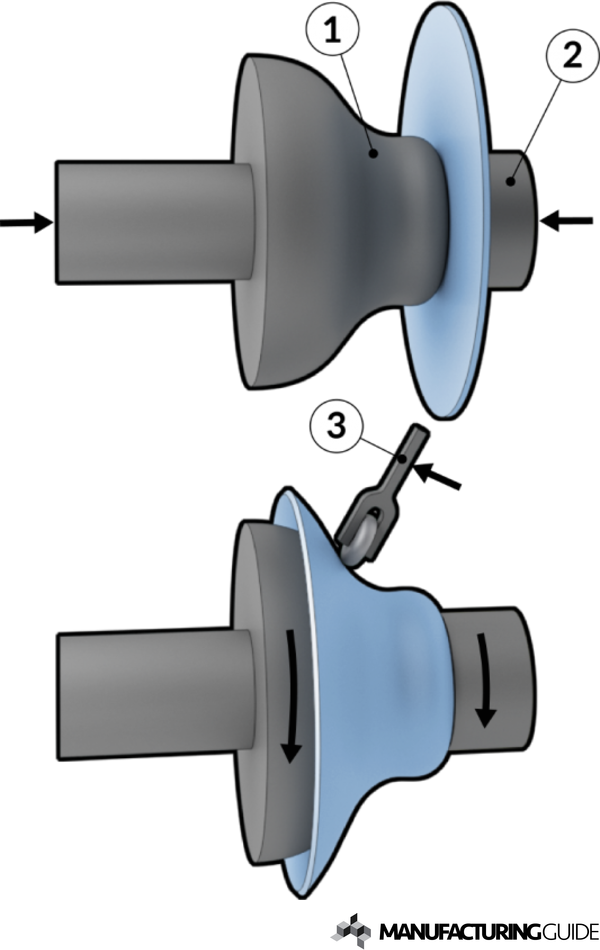

Metal spinning is a method of forming rotationally symmetrical sheet metal parts. In spinning, the sheet metal discs are formed into rotationally symmetrical hollow shapes. The blank is clamped between the shaped spinning mandrel and the tailstock of the spinning machine and rotated by the main drive.

What are the application of spinning?

Applications and Uses of Spinning: Most of metals that are available in sheets can be spun. The most commonly used are: Aluminum, Copper, brass, stainless steel, carbon steel etc. 2. Molybdenum, titanium, and magnesium alloys are usually spun by hot spinning process.

Why is metal spinning used?

Metal spinning can be used to produce single items in a cost-effective manner, as well as a small run of parts made from high-cost materials like platinum. Or, you can run large quantities of aluminum or copper parts for a fairly low price.

What is spinning and flow turning?

Flow turning or spinning is the plastic deformation of metal to the shape of a rotating mandrel with forces applied by a tool or roller.

What is spinning in product design?

Metal spinning is a method of forming rotationally symmetrical sheet metal parts. In spinning, the sheet metal discs are formed into rotationally symmetrical hollow shapes. The blank is clamped between the shaped spinning mandrel and the tailstock of the spinning machine and rotated by the main drive.

What are the application of spinning?

Applications and Uses of Spinning: Most of metals that are available in sheets can be spun. The most commonly used are: Aluminum, Copper, brass, stainless steel, carbon steel etc. 2. Molybdenum, titanium, and magnesium alloys are usually spun by hot spinning process.

What is spinning in steel?

What is hot spinning process?

“Hot spinning” involves spinning a piece of metal on a lathe while high heat from a torch is applied to the workpiece. Once heated, the metal is then shaped as the tool on the lathe presses against the heated surface forcing it to distort as it spins.

Which lubricant is used in spinning operation?

CVC Texlube Knotter Cleaner Spray also known as Splicer/Knotter Cleaner is non-staining cleaner-cum-lubricant for modern textile machinery used for various operations such as spinning, winding and weaving, knitting etc.

What is spinning process in lathe machine?

Also known as metal turning, metal spinning is a type of metalworking process that involves the use of a rotating machine — typically a CNC lathe — to deform metal over a pre-shaped mold. Unlike with other metal turning processes, however, it doesn’t strip away or otherwise remove any of the metal material.

What is metal spinning machine?

Metal spinning is a form of symmetrical metalworking where a flat circle, or circular, piece of metal is fitted into a hand lathe or CNC lathe. Held in place by a pressure pad, the metal disk is spun at an appropriate speed.

Who invented metal spinning?

The Rise Of CNC Metal Spinning NC technology was originally invented by John T. Parson in the 40’s working closely with the MIT (Massachusetts Institute of Technology) which was later commissioned by the United States Air Force.

What is conventional spinning?

Metal spinning, also called conventional spinning or just spinning, is the forming of an axis-symmetric part over a rotating mandrel. Force is delivered by a tool with a rounded end or a roller. A flat, or possibly preformed, work piece is held between a mandrel and tail stock.

What is flow forming?

Flow Forming Technology involves the application of pressure to the inner barrel of the wheel, while spinning and after it has been casted. This process stretches and compresses the aluminum, which increases tensile strength.

What is the purpose of flow forming?

Flow forming is ideal for manufacturing parts out of high-strength materials; the process’s high forming forces can produce these parts within tight dimensional and thickness tolerances.

What is shear forming explain?

Shear forming, also referred as conical flow forming (concave and convex flow forming) or shear spinning, is an incremental metal forming process similar to metal spinning. But in shear forming, the diameter of the final piece is approximately equal to that of the original flat sheet metal blank.

What do Metal Spinners make?

What Is Metal Spinning? Spinning metal is similar to the process by which clay pots are made. Pieces of flat circular metal are placed into a hand or CNC lathe. It’s generally used for forming metal disks which can be configured into a variety of products.

What is spinning in product design?

Metal spinning is a method of forming rotationally symmetrical sheet metal parts. In spinning, the sheet metal discs are formed into rotationally symmetrical hollow shapes. The blank is clamped between the shaped spinning mandrel and the tailstock of the spinning machine and rotated by the main drive.

What are the application of spinning?

Applications and Uses of Spinning: Most of metals that are available in sheets can be spun. The most commonly used are: Aluminum, Copper, brass, stainless steel, carbon steel etc. 2. Molybdenum, titanium, and magnesium alloys are usually spun by hot spinning process.

What is spun Aluminium?

Aluminium is just one of the many metals that Metspin can work with. Aluminium is lightweight & durable with a good corrosion resistance and boasts the cost effectiveness of mild steel.

What is spun copper?

Copper Metal Spinning or Spin Forming Copper, known for its decorative look has high resistance to heat, and electrical conductivity. A soft metal that is easy to work with, copper has become less popular in traditional manufacturing circles due to the high material costs.